In todays fast-paced world of product development, rapid prototyping stands as a crucial process that allows innovators to bring their ideas to life with remarkable speed and efficiency. However, as exciting as the prospect of turning concepts into tangible models may be, understanding the associated costs can often be a daunting task.

From materials and technology to labor and iteration cycles, the financial landscape of rapid prototyping is multifaceted. Whether you’re a startup testing the waters of a new invention or a well-established company looking to streamline your design process, knowing what to expect in terms of expenses is vital for effective planning.

In this article, we will delve into the various components that influence rapid prototyping costs and offer practical tips to help you budget effectively, ensuring that your creative ambitions don’t get stifled by unexpected financial hurdles.

Introduction to Rapid Prototyping Costs

In today’s fast-paced product development landscape, understanding the costs associated with rapid prototyping is essential for anyone looking to bring innovative ideas to life. Rapid prototyping—an invaluable process that allows designers and engineers to create physical representations of their concepts in record time—can vary significantly in expense based on several factors. Materials, technology, and the complexity of the design play pivotal roles in shaping your budget. Additionally, the choice between in-house development and outsourcing production can further complicate financial forecasts.

Opting for professional rapid prototyping services can offer advantages such as access to advanced technologies and expertise, potentially influencing both cost and efficiency. As you navigate this multifaceted terrain, being equipped with insights into potential costs will empower you to plan effectively, minimizing delays and discovering more efficient pathways to success. Whether you’re a startup or an established enterprise, mastering the intricacies of these costs is a cornerstone of achieving your project goals without overspending.

Technology Choices: 3D Printing vs. CNC Machining

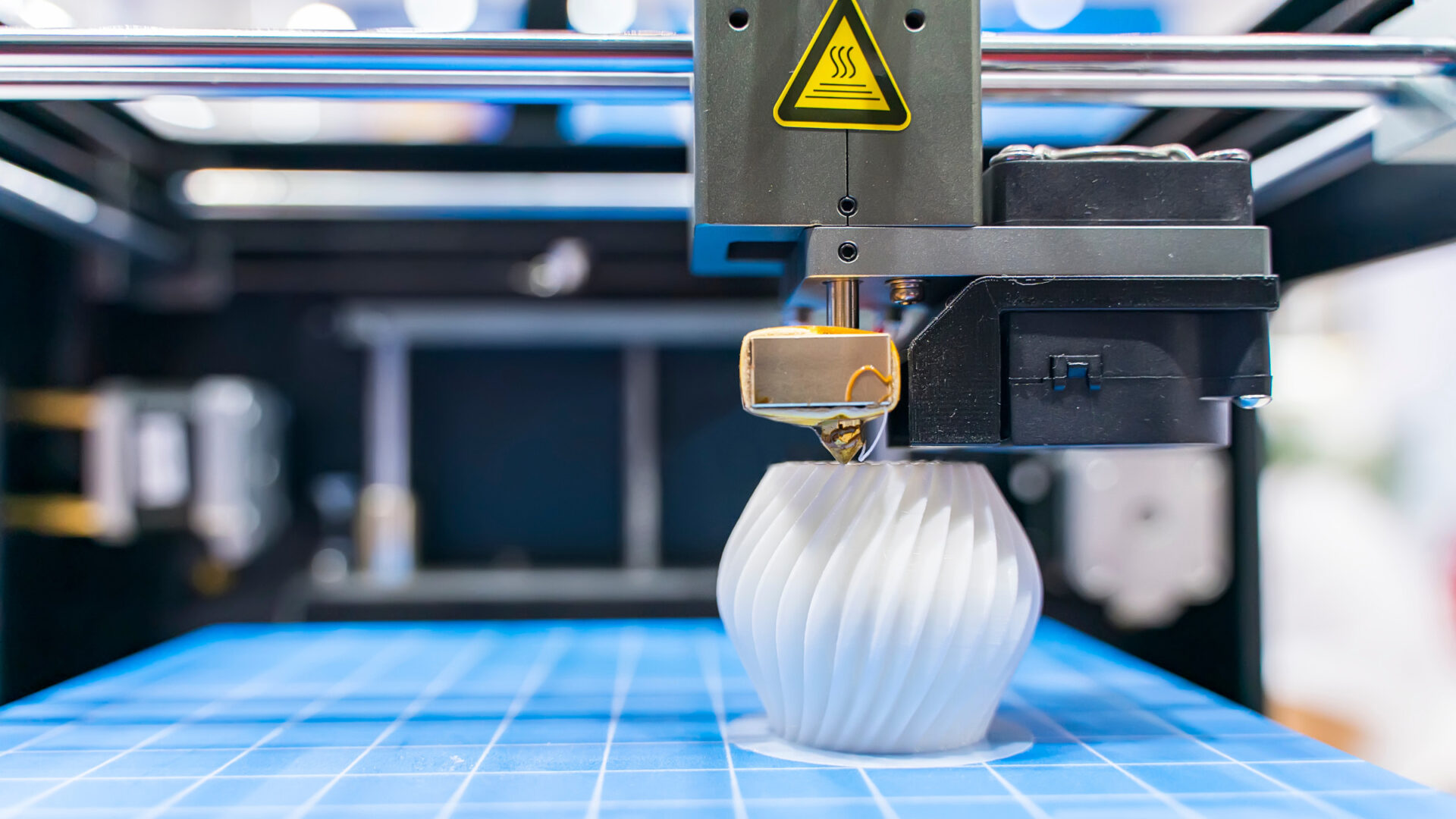

When evaluating technology choices for rapid prototyping, the decision between 3D printing and CNC machining can significantly impact both costs and project timelines. 3D printing, with its layer-by-layer additive process, offers unparalleled flexibility, allowing for intricate designs without the need for costly tooling.

This method can be especially advantageous for prototyping one-off designs or short production runs, as materials and setup costs may remain relatively low. However, it’s important to recognize the potential limitations in material strength and finish quality compared to traditional methods.

On the other hand, CNC machining, which involves subtractive manufacturing techniques, often excels in producing parts with tight tolerances and a superior surface finish. While initial setup and machine time can be more expensive, especially for complex projects requiring multiple operations, the durability of machined parts often justifies the cost for larger-scale production.

Ultimately, the choice hinges on specific project needs—budget constraints, desired material properties, and the intended application—creating a dynamic landscape that requires careful consideration.

Budgeting Tips for Rapid Prototyping

When embarking on the journey of rapid prototyping, its essential to keep a keen eye on your budget to ensure your project remains viable. Start by clearly defining your project scope; this will help you avoid unnecessary costs and focus on what truly matters.

Consider leveraging open-source software and existing materials to minimize expenses. Collaborate closely with your team to prioritize features, eliminating any non-essential elements that might inflate costs.

Additionally, don’t shy away from seeking quotes from multiple vendors—this can unveil competitive rates that fit within your financial parameters. Finally, set aside a contingency fund to address unexpected challenges, ensuring your prototyping process remains fluid and adaptable.

By being strategic and resourceful, you can navigate the complexities of budgeting and set the stage for a successful prototyping experience.

Conclusion

In conclusion, understanding the costs associated with rapid prototyping is crucial for effective budget planning, whether youre a startup or an established business. By considering factors such as material selection, design complexity, and the overall scope of your project, you can better anticipate expenses and allocate resources efficiently.

Engaging with professional rapid prototyping services can further streamline this process, offering expertise and technology that can significantly reduce costs and time-to-market. By being informed and strategic about your budgeting, you can leverage rapid prototyping to enhance product development, innovate faster, and ultimately stay competitive in your industry.